Vibration Analysis

Vibration measurement and analysis is a vital part of determining the condition of your assets.

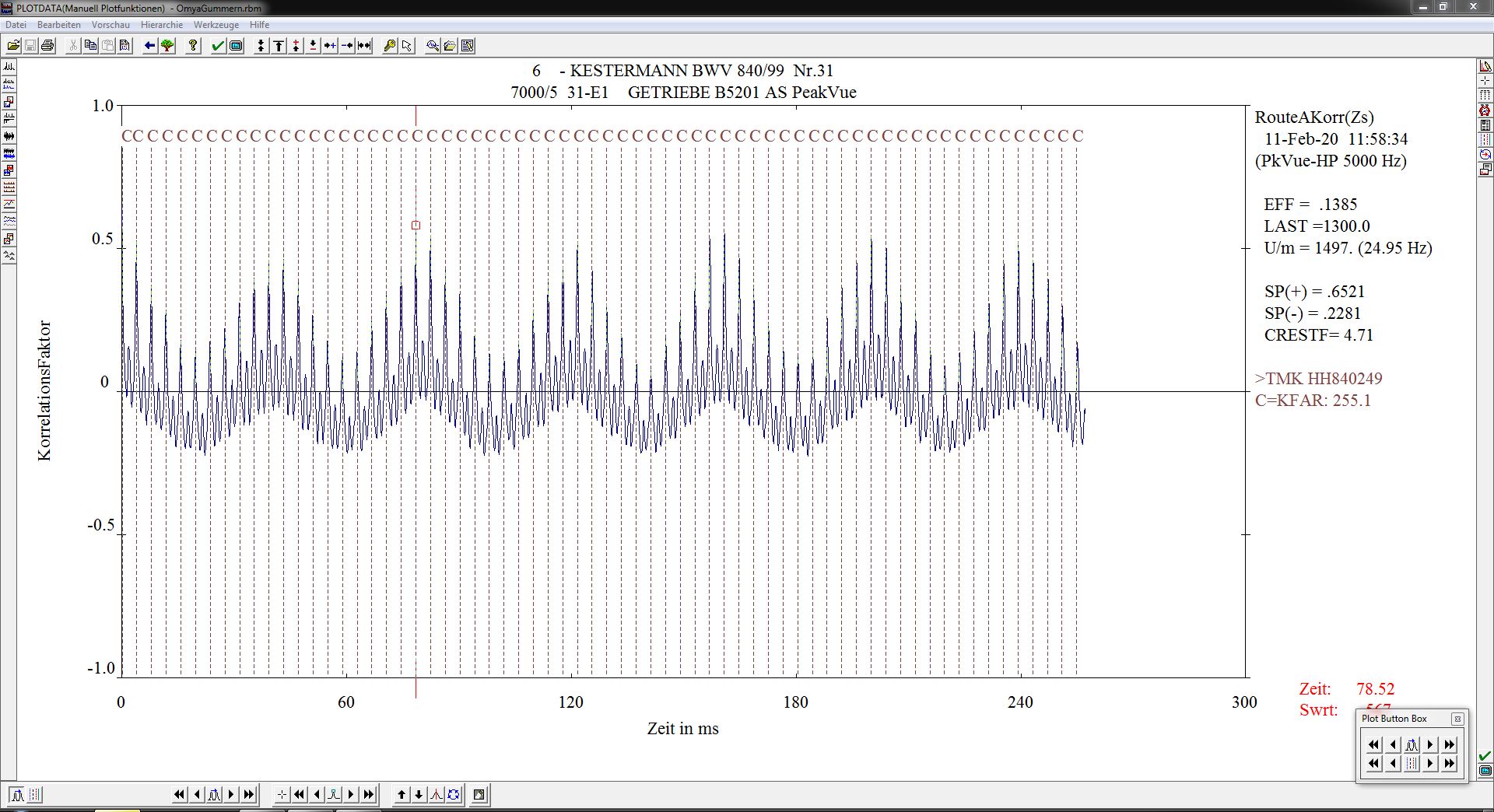

Vibration is measured, typically using a sensor to measure the acceleration, on different parts of rotating machines.

It is a an good early-detection system for faults on rotating equipment resulting from:

- Unbalance

- Bearing damages

- Gearboxes: Tooth wear

- Misalignment

- Bent shaft

- Loosness

- Motor damages

- and much more…

Vibration analysis should be done on a regular basis, in order to always have a correct knowledge of an asset.

“…But I know that my machine can vibrate with XX mm/s without any problem…”

Vibration Analysis is much more than just measuring the sum of the vibration (in mm/s).

Through the analysis , the source of the vibration can be determined, and any increase of a damage can be detected.